产品简介

测量口径 | (DN10-DN2000)可以定制其他规格 |

| 精度等级 | ±0.2~0.5级 |

电导率 | ≥50US/cm |

防护等级 | IP65,IP68 |

供电方式 | AC220V/DC24V(标准);电池电源可以定制 |

通讯模式 | RS485,Modbus,GPRS,Profibus-DP,Hart,Wifi等。 |

安装方法 | 默认法兰连接(法兰连接、螺纹、卡箍可定制 |

结构图

|  |  |

结构图

|  |  |  |

| 1. 匠心工艺 产品本体平面光滑,加工工艺精湛 产品漆面防潮防锈 |  |

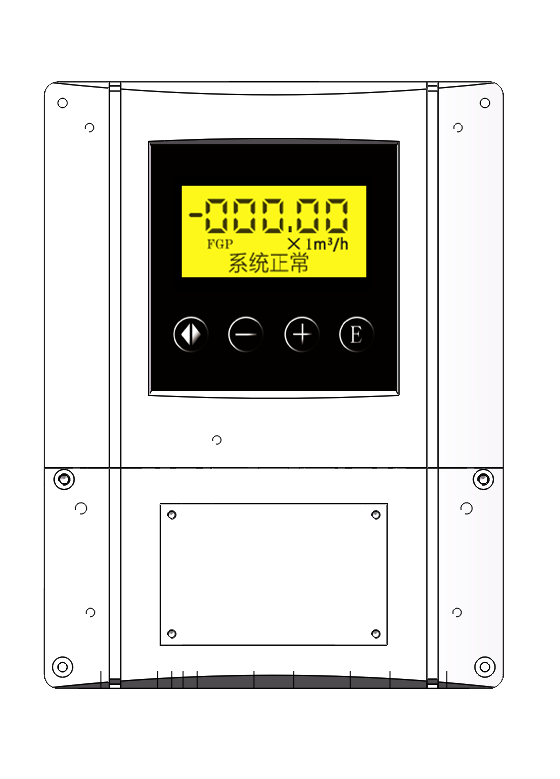

| 2. 智能表头 清晰实时流量显示,累计流 量显示,支持Modbus,Profibus-dp,GPRS,Wifi,Hart等通讯协议,支持远程APP功 |

3.非导磁不锈钢本体 采用优质非导磁导管 |  |

| 4.三防型衬里 采用防脱落、防翻边、防漏水的材质, |

外壳强韧耐磨 采用专业定制钢材打造的外壳,采用先进的激光焊接技术 | 升级转换器 升级转换器,性能更稳定,零漂移,重复性更低测量更精确 | 纯铜线圈 采用国标纯铜线圈、专业定制,双层绝缘隔离,性能更可靠,使用寿命更长 |

|  |  |

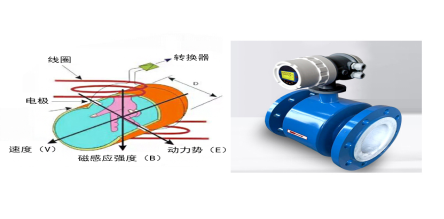

根据法拉第电磁感应原理,在于测量管轴线和磁力线相垂直的管壁上安装了检测电极,当导电液体沿测量管轴线运动时导电液体切割磁力线产生感应电势,此感应电势由检测电极检出,数值大小与流量成正比例,其值为:E=KBVD试中

E-感应电势

K-与磁场分布及轴向长度有关的系数

B-磁感应强度

V-导电液体平均流速

D-电极间距(测量管内直径)

量程范围选型表

| 速度-流量对照表 | |||||||

| 流速 | 0.01 (最小) | 1 | 2 | 3 | 4 | 5 | 15 (最大限度) |

| 通径 | |||||||

| 15 | 0.0113 | 0.6362 | 1.2723 | 1.9085 | 2.5447 | 3.1809 | 9.5426 |

| 20 | 0.0177 | 1.1310 | 2.2619 | 3.3929 | 4.5239 | 5.6549 | 16.9646 |

| 25 | 0.0452 | 1.7671 | 3.5343 | 5.3014 | 7.0686 | 8.8357 | 26.5072 |

| 40 | 0.0707 | 4.5239 | 9.0478 | 13.5717 | 18.0956 | 22.6195 | 67.8584 |

| 50 | 0.1195 | 7.0686 | 14.1372 | 21.2058 | 28.2743 | 35.3429 | 106.0288 |

| 65 | 0.1810 | 11.9459 | 23.8918 | 35.8377 | 47.7836 | 59.7295 | 179.1886 |

| 80 | 0.2827 | 18.0956 | 36.1911 | 54.2867 | 72.3823 | 90.4779 | 271.4336 |

| 100 | 0.6362 | 28.2743 | 56.5487 | 84.8230 | 113.0973 | 141.3717 | 424.1150 |

| 150 | 1.1310 | 63.6173 | 127.2345 | 190.8518 | 254.4690 | 318.0863 | 954.2588 |

| 200 | 0.2827 | 113.0973 | 226.1947 | 339.2920 | 452.3893 | 883.5729 | 1696.4600 |

| 250 | 1.7671 | 176.7146 | 353.4292 | 530.1438 | 706.8583 | 1272.3450 | 2650.7188 |

| 300 | 2.5447 | 254.4690 | 508.9380 | 763.4070 | 1017.8760 | 1731.8030 | 3817.0351 |

| 350 | 3.4636 | 346.3606 | 692.7212 | 1039.0818 | 1385.4424 | 2261.9467 | 5195.4089 |

| 400 | 4.5239 | 452.3893 | 904.7787 | 1357.1680 | 1809.5574 | 2862.7763 | 6785.8401 |

| 450 | 5.7256 | 572.5553 | 1145.1105 | 1717.6658 | 2290.2210 | 3534.2917 | 8588.3289 |

| 500 | 7.0686 | 706.8583 | 1413.7167 | 2120.5750 | 2827.4334 | 5089.3801 | 10602.8752 |

| 600 | 10.1788 | 1017.876 | 2035.7520 | 3053.6281 | 4071.5041 | 6927.2118 | 15268.1403 |

| 700 | 13.8544 | 1385.4424 | 2770.8847 | 4156.3271 | 5541.7694 | 9047.7868 | 20781.6354 |

| 800 | 18.0956 | 1809.5574 | 3619.1147 | 5428.6721 | 7238.2295 | 11451.1052 | 271,433,605 |

900 900 | 22.9022 | 2290.2210 | 4580.4421 | 6870.6631 | 9160.8842 | 14137.1669 | 34353.3157 |

| 1000 | 28.27437 | 2827.4334 | 5654.8668 | 8482.3002 | 11309.7336 | 20357.5204 | 42411.5008 |

1200 1200 | 40.7150 | 4071.5041 | 8143.0082 | 12214.5122 | 16286.0163 | 27708.8472 | 61027.5612 |

| 1400 | 55.4177 | 5541.7694 | 11083.5389 | 16625.3083 | 22167.0778 | 36191.1474 | 83126.5416 |

1600 1600 | 72.3823 | 7238.2295 | 14476.4589 | 21714.6884 | 28952.9179 | 28952.9179 | 108573.442 |

| 1800 | 91.6088 | 9160.8842 | 18321.7684 | 27482.6525 | 36643.5367 | 45804.4209 | 137413.2627 |

2000 2000 | 113.0973 | 11309.7336 | 22619.4671 | 33929.2007 | 45238.9342 | 56548.6678 | 169646.0033 |

| 2200 | 136.8478 | 13684.7776 | 27369.5552 | 41054.3328 | 54739.1104 | 68423.8880 | 205217.6640 |

2400 2400 | 162.8602 | 16286.0163 | 32572.0326 | 48858.0490 | 65114.0653 | 81430.0816 | 244290.2448 |

| 2600 | 191.1343 | 19113.4268 | 38226.8536 | 57340.2804 | 76453.707 | 295567.134 | 286701.402 |

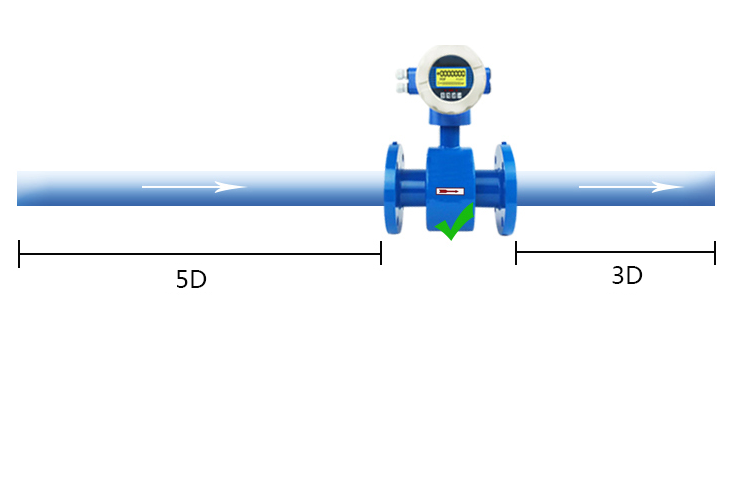

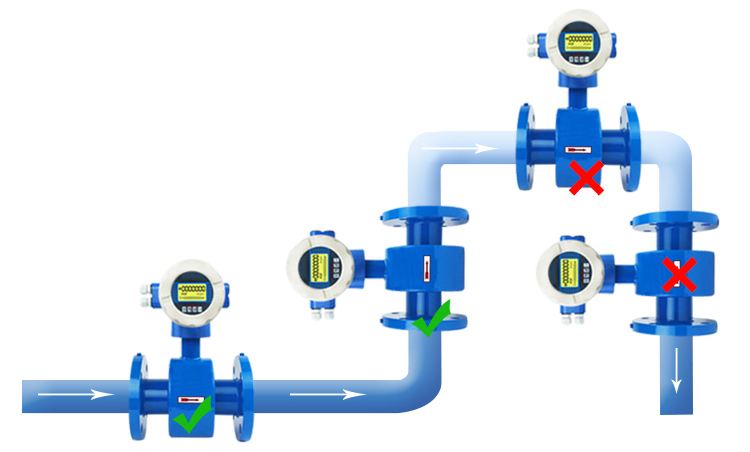

| 1.流量计前方最少需要有5*D(D为流量计内径) 长度的直管段,后方要有3*D长度的直管段 | 2.应安装在管道上升 | 3.安装在水平管道较低处和垂直向上处, 避免安装在管道上的最高点和垂直向下处 | 4.在开口排放管道安装,应安装在管道较低处。 |

|  |  |  |